The image for Day 144 of VM_365 is of a bone double ended pin beater found in the fill of a pit at a small middle Saxon site excavated near St Mildred’s Bay, Westgate in 2006.

Pin beaters were used to beat down threads while using a warp weighted loom.

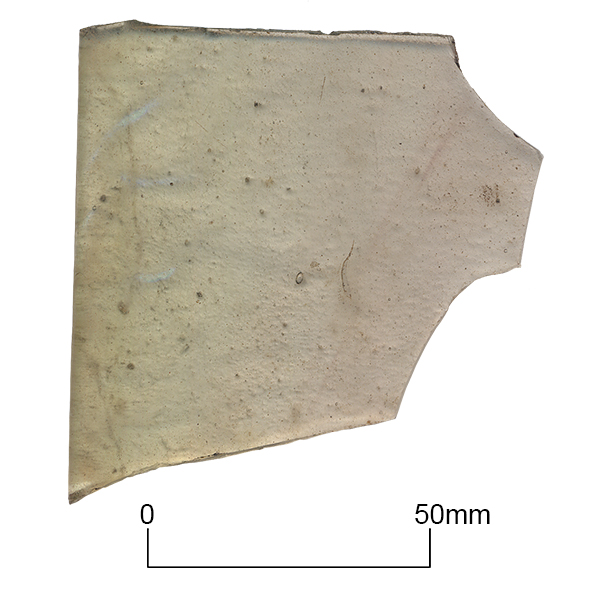

The pin beater is made of bone or ivory and measures 121 mm long, 3mm at its narrowest point at the end and 8mm at its widest point at the centre. It has an ovoid, slightly flattened profile and has been polished through use to a very smooth and glossy finish. Both ends have been carved to form a point.

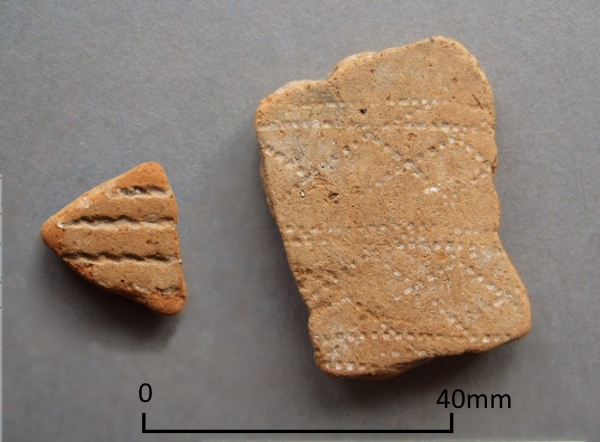

This pin beater was found in the fill of a rectangular pit along with fragments of burnt daub, animal bone and marine shell, as well as a single pottery sherd from a jar dating between 450-700 AD.

Other finds from the same site included large fragments of burnt daub with rod and sail impressions and an iron lock mechanism possibly from a chest or casket.

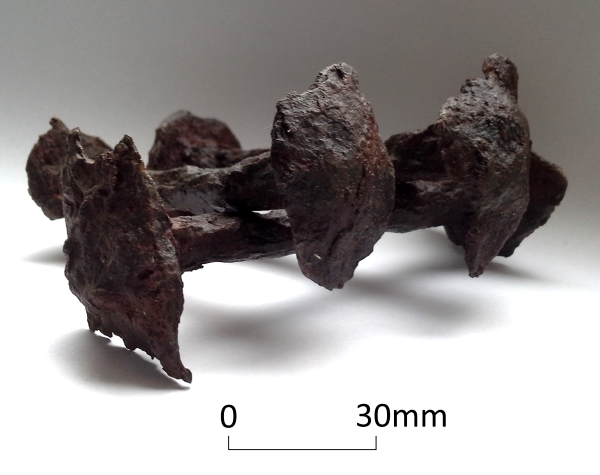

Day 139’s VM_365 image shows a Roman lock fastener from the villa at Minster.

Day 139’s VM_365 image shows a Roman lock fastener from the villa at Minster.